Our team of experts in the tequila world will provide you with all the necessary tools to answer any questions that may arise about our product.

We offer quality in each of our profiles, we seek to be your bulk supplier to meet your objectives. We will work closely with the client to prepare the organoleptic profile of the product.

The distillery takes the best of traditional tequila making methods and blends them with industry innovation, this allows us to develop a very wide range of profiles.

REVOLUTIONIZING

THE MAQUILA INDUSTRY

The Tequila Production Maquila System

Private Labels and the Maquila Industry

What are the strong points

that Casa Loy has as an advantage

in the production process?

Distillery experience

Our maquila factory is staffed by a team of seasoned professionals with decades of experience in tequila production.

State-of-the-art facilities

Our commitment to excellence ensures that your tequila is made under optimum conditions, ensuring consistency, purity and an exceptional drinking experience.

Custom flavor profiles

It offers the flexibility to create custom flavor profiles, from the agave selection process to aging techniques.

Brand development support

Our team of experts can provide valuable insight and guidance in refining your brand identity, packaging design, and marketing campaigns.

Optimized production process

Our efficient operations and meticulous planning ensure timely delivery and perfect inventory management.

Our Advantages Casa Loy

Precision Craftsmanship

At our maquila factory, we embrace a philosophy of precision craftsmanship. Each step of the production process is executed with meticulous care and attention to detail.

Smart Distillation

By focusing on specific quantities, we are able to closely monitor and adjust each batch, ensuring that every bottle of tequila that leaves our facility meets our exacting standards.

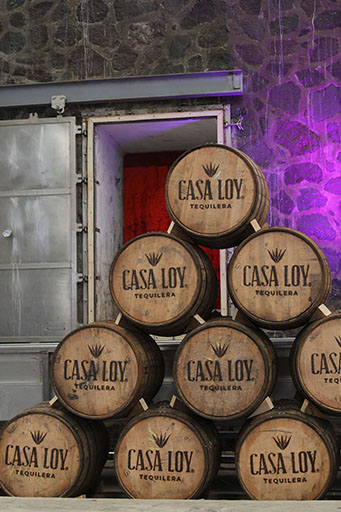

Maturation Mastery

A key strength of our production process lies in our mastery of ripening. We understand that the aging period is crucial for the development of complex flavors and the smoothness that characterizes an exceptional tequila.

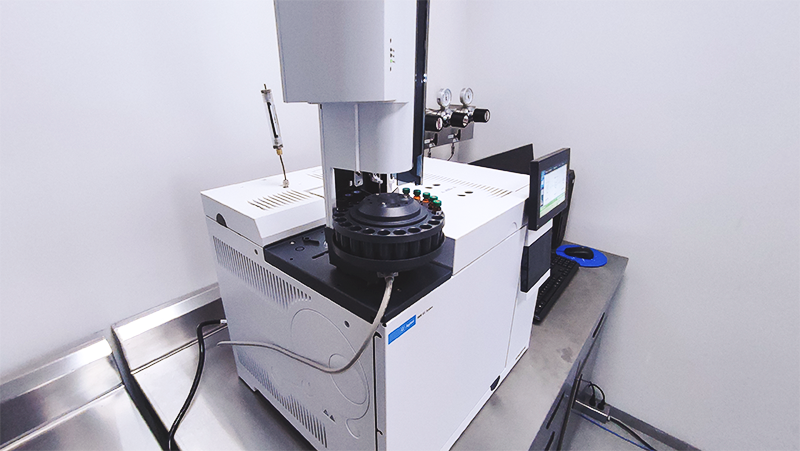

Quality Control at Every Stagep

Quality control is ingrained in all aspects of our production process. Our state-of-the-art laboratories and experienced technicians perform extensive testing and analysis to ensure that each batch meets our strict quality standards.

Sustainability and Social Responsibility

Our production process incorporates environmentally friendly practices, minimizing waste and energy consumption. In addition, we actively support local communities and adhere to fair trade principles, ensuring that our operations have a positive impact on the lives of those involved in the tequila supply chain.

International certifications

Obtained certifications: KOSHER ORGANIC USDA UE ORGANIC / In process: ISO

Masonry Ovens

Our maquila factory uses traditional masonry ovens in the tequila manufacturing process, adding a touch of authenticity and traditional techniques to your tequila production.

Autoclaves

Autoclaves offer a modern approach to cooking agave piñas, using steam and pressure to speed up the cooking process and maintain the integrity of the agave flavors.

Diffuser

The diffuser is state-of-the-art technology that extracts the sugars from the agave using water and pressure. This method allows for a higher extraction rate and greater efficiency in tequila production. By using the diffuser, we are able to create a tequila with a distinctive flavor profile, characterized by its purity and clarity.

Tahona

The tahona is a traditional stone wheel used to crush and extract juices from agave piñas. By adopting the tahona process, your tequila will evoke a sense of authenticity and craftsmanship sought by the most discerning consumers.

Laboratory

In our laboratory we are fully equipped by a chromatographer to assure all the characteristics in each batch of production.

Production capacity

9 Million liters per year

in distillation columns

4.5 Million liters

per year in stills

+ 1 Million liters

inventory capacity

1 Million liters

aging capacity

We want you to be part of our house

Horarios

- Lunes - sábado 08:00 am - 09:00pm

- Domingo Cerrado

Contacto

- Dirección : Carretera Ayotlán-Atotonilco km 6.5 Las Villas, 47930, 47930, Ayotlán, Jal.

- Whatsapp: +52 1 348 100 6137

- Email contact@casaloy.com

Copyright © 2023 Casa Loy Tequilera. Todos los derechos reservados.